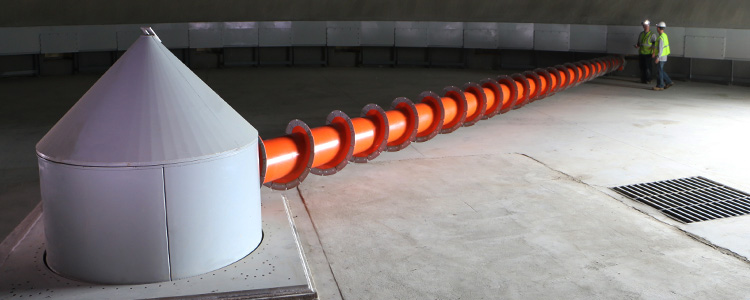

Laidig designs and builds totally automated reclaim systems for extreme-duty applications.

Our systems provide higher delivery rates and greater storage capacity for materials with poor flow characteristics, such as powders, chemicals, and other bulk solids. Some examples of these materials include sugar and trona.

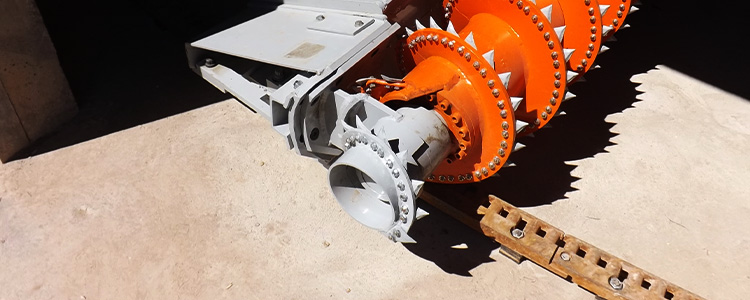

Laidig offers a complete line of Cone-Bottom, Cantilever, and Track-Drive Model reclaim systems that combat bridging and rat-holing problems that are associated with abrasive, sticky, fibrous, or hard-to-handle materials.

Consistent exposure to rugged and abrasive materials can lead to premature wear and the reduction in the life expectancy of critical Laidig reclaimer components. To prevent this, Laidig has done extensive research and development to provide the very best abrasion resistance options specifically to ensure your equipment will hold up even in the harshest of conditions. These Laidig options include: hardened flight, carburized auger knives and blades, and a total hard-facing of the auger flighting and tube.

Laidig Reclaim Systems help create mass flow by enabling near-total cleanout, while maintaining a first-in-first-out (FIFO) inventory control. These systems can be installed into new silos or retrofitted into existing structures, and are customized to handle a wide variety of materials, including: powders, chemicals, meals, wood residues, and many other bulk materials.

For the ease of maintenance and for the safety of all on-site personnel, all Laidig reclaimer drive systems are located external to the stored material.