Laidig has designed an innovative way to efficiently store and reclaim high-volume materials that can be fluidized.

Our fully automated Fluidized Screw Reclaim System is a cost-effective method for the large-capacity storage and reclaim of cement and other fluidizable materials such as fly ash, talc, and powders.

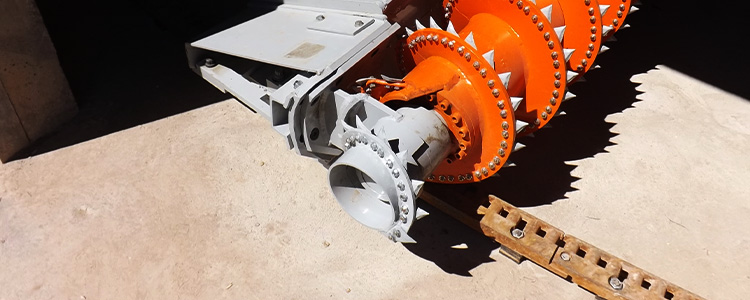

The Fluidized Screw Reclaim System is a “hybrid” reclaim solution combining the use of aeration conveyors and a rugged mechanical final cleanout auger. Aeration conveyors are laid out as “spokes” and are used for primary material unloading. The fully reversible reclaim auger then provides a safe, “Zero Entry” solution for final cleanout.

Laidig offers proven performance and reliability for cement storage and reclaiming applications ranging between 120 and 190 feet (37m–58 meters), and air conveyance rates of up to 225 cubic feet per minute (cfm).

We can also provide several other systems that might work better for your application, depending on your specific needs.

Application Spotlight: Laidig's Unique Hybrid Reclaiming Solution for Cement

"Cement storage and handling is a complicated science. When St Marys Cement evaluated options for their new storage projects, Laidig Systems, Inc. was able to provide them with an innovative solution..."