Laidig has decades of experience providing innovative storage and reclaim solutions for port facility applications.

Our large capacity reclaim systems are a critical component to the operational efficiency of a port facility. They provide tremendous flexibility and reliably offer significant load-out rates.

Laidig engineers and designs FULLY AUTOMATED large-diameter bulk storage and reclaim systems for large capacity storage silos to meet the needs and requirements of port facility applications that include our Track-Drive and X-Traktor Reclaim Systems.

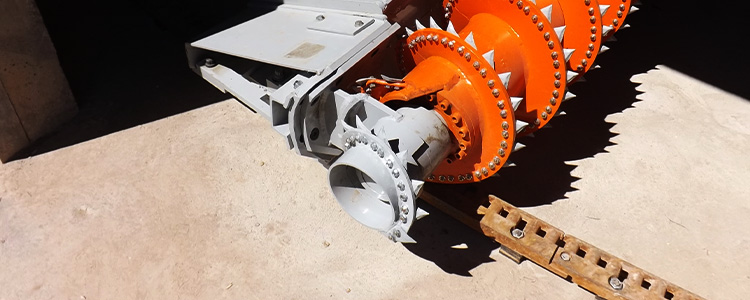

The Laidig Track-Drive Reclaim System is engineered to provide a fully automated, near-total cleanout while promoting first-in-first-out (FIFO) material distribution. The advance track-drive system ensures a positive advance, and the unique self-cleaning shoe assembly firmly grips the ductile iron track, keeping the auger in place.

The Laidig X-Traktor Reclaim System is customized to a wide variety of applications in silos or domes, and is available in both cantilever and trolley-supported systems. The X-Traktor is Laidig's largest and most powerful reclaimer, designed specifically for dependability and low maintenance.

All of these Laidig Reclaim Systems offer maximum storage and automated delivery with fully automated, push-button operation.

Laidig reclaim systems provide solutions to the challenges port facilities encounter that include:

- First-In-First-Out (FIFO) Inventory Control

- Elimination of Bridging and Rat-Holing

- Controlling product infestation

- Controlling product contamination

- Providing “near-total” cleanout

- Providing “zero entry” for easy service access and operator safety

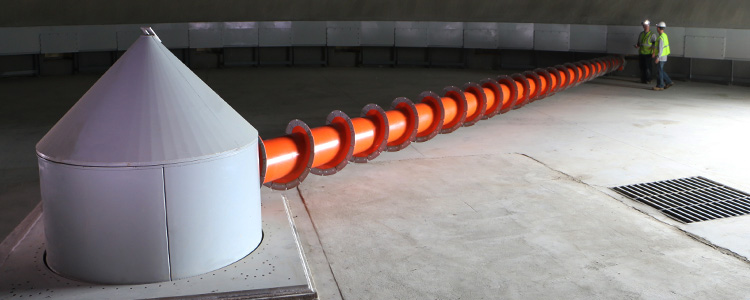

Project Spotlight: Laidig Provides Multiple Reclaimers to Brazilian Port Facility

"The eight Laidig reclaimers will deliver trans-loaded soybean meal, corn, and/or whole soybeans at a rate of roughly 500 MTPH per reclaimer to a conveyer system that will load ocean-going ships..."