What sets Laidig's manufacturing facility apart from the rest?

Large, Dedicated Facility

Over 135,000 sq. ft. of factory space

Components Made In-House

Custom-built augers, gearboxes & more

State-of-the-Art Tools

Massive lathes & robotic welding technology

Qualified, Certified Employees

Highly skilled welders, machinists & managers

Vertical Integration

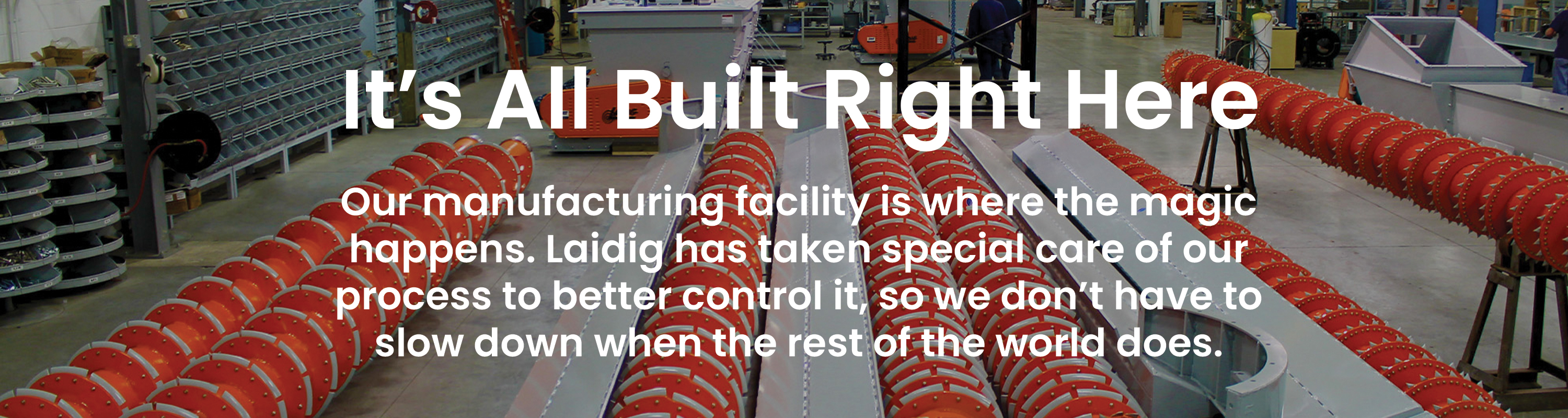

We fabricate, fit, and weld our own auger flighting using state-of-the-art machinery and a robotic welder system. It allows us to make custom flighting for any shape or size of auger.

Laidig has developed a number of reclaimer gearboxes that better suit the unique environment in which the reclaimers operate. These rugged gearboxes—designed specifically for the Laidig reclaimer—provide consistent high torque to the auger while minimizing premature wear on critical gears and bearings.

We have the very best abrasion resistance options—and the tools to bring them to life. Our options were developed specifically to ensure your equipment will hold up in the harshest of conditions.

What we can do: hardened flighting, carburized auger knives and blades, and complete hardfacing of auger tube and flighting.

Many Laidig reclaimers are powered hydraulically for safety and efficiency. Due to our unique power demands, we develop and manufacture our Hydraulic Power Units in-house. These units generate maximum power, ensure the machine is working how it should, and provide real-time performance feedback.

What Happens After It's Built?

The next step in our process is validation testing—and it's a test we never skip.